In this new Chronicle, I unveil the unsuspected expertise of the G&F Châtelain Manufacture, the watchmaking arm of the famous Chanel brand! Although all – or almost all – of us are acquainted with Gabrielle Chanel, the strong-willed woman and fashion designer behind the eponymous Haute Couture brand, it seems to me that the impressive watchmaking of the House she founded is often overlooked. After being lucky enough to explore the heart of Chanel's watchmaking division within the walls of the G&F Châtelain Manufacture in La Chaux-de-Fonds, I am pleased to share with you in this column some well-kept secrets that may change your vision of Chanel watchmaking.

The G&F Châtelain Manufacture

In my introduction, I deliberately associated the names Chanel and G&F Châtelain. Two different names and yet one and the same company! So, what is the G&F Châtelain Manufacture and why isn't it simply called the "Manufacture Chanel"?

A brief historical review of the history of the Manufacture and its ties with Chanel.

The initials of G&F Châtelain stand for Georges and Francis Châtelain, two brothers who decided in 1947 to create a Manufacture and to specialise in finishing of movements, crafting gold models as well as other horological and jewellery skills.

Since its creation, the Manufacture has never ceased to develop by diversifying its expertise, always geared towards satisfying its watchmaking clients (development of skills in polishing techniques to assert its know-how in case and movement finishing; diversification of its production facilities towards precision tooling and new stamping technologies; production of metal bracelets, etc.).

By registering the "C" maker’s mark in 1967, the G&F Châtelain Manufacture officially acknowledged its reputation as a market player ready to promote a quality label of craftsmanship and precision.

On into the 1980s, the G&F Châtelain Manufacture established its position as a masterful project manager for all the watchmaking products entrusted to it by a demanding clientele, including Chanel. In 1987, the Chanel Première was born. This was the first watch offered by the Haute Couture brand, and its origins were the inspiration for the model's name (première being the French term for head seamstress).

The beautiful Carole Bouquet wearing the Première watch launched in 1987

A few years later, in 1993, this partnership and convergence led to the purchase of the G&F Châtelain Manufacture by the Chanel company.

Chanel, custodian of artisanal expertise

By acquiring the G&F Châtelain Manufacture in 1993, Chanel maintained the latter’s corporate name, but also and above all its freedom of action and its personality. Chanel thus became the owner but also the custodian of this watchmaking expertise.

This was not the first time Chanel had done something of this nature. In fact, through its subsidiary Paraffection, Chanel had a policy of acquiring – with the aim of safeguarding and preserving the French artisanal heritage – numerous skills in the fields of leather workmanship (the glove maker Causse; the boot maker and "Maître d'art" Massaro; embroidery specialist Lesage; as well as other artistic crafts linked to Haute Couture (Desrues, Lemarié, Michel, Guillet,...) In all instances, each company retains its name, its creative freedom and its identity.

Chanel had not restricted this dynamic to French expertise alone, notably broadening its reach by acquiring the G&F Châtelain Manufacture, as well as by taking shares in the Haute Horlogerie companies Romain Gauthier and F.P. Journe. Not to mention its very strong ties with the Kenissi Manufacture which we will discuss a little later...

Chanel: genuine watchmaking credentials

The watchmaking world is very tough and always extremely critical when it comes to welcoming new players to the market. We often talk about watchmaking legitimacy or credibility. But what are the criteria for determining whether a watch company is legitimate or credible?

In the case of Chanel, if legitimacy is found in longstanding expertise, then yes, Chanel is totally legitimate because the company in fact draws on more than 75 years of expertise and perpetual development in the field of watchmaking through the G&F Châtelain Manufacture.

Credible? One need only take a look (and even through a magnifying glass) at the precision work done by the workshops of Romain Gauthier and François-Paul Journe to recognise that in terms of design quality and watchmaking finishes, Chanel has partnered with the best in their category.

Romain Gauthier Movement

F.P. Journe Anniversary Movement

When Chanel presented its Monsieur de Chanel in 2015 equipped with its first in-house movement, Calibre 1, it had clearly decided to offer an absolutely splendid watch featuring a sophisticated movement with a large jumping hour display at 6 o'clock, small seconds in the centre and retrograde minutes on a 240-degree sector! This was no mean feat and technically speaking represented a movement that was as exceptional in terms of its specifications as its finishing. Judge for yourself!

Monsieur de Chanel and its Calibre 1

Chanel, creator of icons

The Chanel Première watch launched in 1987, with a design inspired by the Place Vendôme in Paris, is a model whose visual identity has become an icon in ladies' watchmaking. This understated and discreet timepiece is the epitome of feminine elegance. For three years in a row from 2017 to 2019, Chanel won the Ladies’ Watch Prize in the Grand Prix d’Horlogerie de Genève. Watchmaking expertise and refinement are the twin attributes of this icon!

In 2000, a new icon was born with the J12, a watch featuring a design recognisable at first glance and made of high-resistance ceramic. It was initially presented in black ceramic and then three years later in pure white ceramic – as that was the time it took the Manufacture (which has full control over the ceramic production process in-house) to develop a perfect white.

Twenty years later, the J12 was redesigned to accommodate a new movement and to incorporate the latest technical developments in the field of ceramics, thus enabling the new J12 to be even more resistant and more accurate!

These new J12s are now equipped with the brand-new Calibre 12.1, created in collaboration with Rolex and Tudor to give life to Kenissi, the entirely new watch Manufacture in which Chanel has a significant stake.

From a watchmaking standpoint, this movement is extremely well conceived, with a sandblasted finish that some might regard as too simple. However, a closer look reveals that there is nothing simple about it, as it is above all very neat and the choice of such a finishing demonstrates a choice of surface that is elegant and refined precisely because it is understated. The openworked oscillating weight is yet another nod to the Chanel symbolism of the play of circles within a circle and enables one to admire the movement.

These chronicles being those of a watchmaker, I suggest we now linger on this Chanel 12.1 movement and the universe surrounding it.

Chanel, a behind-the-scenes yet central player in an extraordinary project

In this truly horological section, I would like to tell you the unknown story behind the origins of this project. This is a little-known and probably exclusive story that we are sharing with you today!

For those who are more interested in Chanel Manufacture Calibre 12.1, they will have heard of the Kenissi Manufacture (which I mentioned earlier). So what does the latter involve? Presented as the industrial arm of Tudor, the Kenissi Manufacture was founded in 2016 in Le Locle in order to produce the brand-new movement developed by Tudor and powering its watches since 2015.

Developed by Tudor? Yes, but...

This is a fascinating saga. For those who have not necessarily followed the story that proved the impetus for this whole adventure, it should be remembered that in 2013 (or perhaps earlier, the timeline can tend to get blurred!) the Swatch Group announced a new policy for the distribution of its movements. The resulted in a whole series of twists and turns that shook up the watch industry, pushing certain players to look for alternatives to the movements supplied by ETA (a firm belonging to the Swatch Group). Among them were Tudor and Chanel.

It all began with a phone call between a handful of people, presenting and explaining the project in a rather discreet way: "So, are you in?” This small group – let’s say composed of about four or five individuals so as to keep things vague and not name anyone – included representatives of Rolex, Tudor and... the G&F Châtelain Manufacture!

This was a top-secret project that absolutely no one else had any idea existed. It involved a handful of ‘secret agents’ meeting on neutral ground, confidentially and never at each other's houses, working in the shadows to develop in secret what would become a few years later in 2015 the very first movement known under the name of MT5621 that would equip the Tudor North Flag watch – and later evolved into Kenissi.

In 2019, Chanel officially took a stake in the Kenissi Manufacture, surprising a large part of the watch industry, which was probably unaware that it was behind the project.

So, what's does this all mean? We spoke earlier of legitimacy and credibility; is that what we are talking about now?

Over the years, Chanel has become not only a major player in the watch industry with an innovative offer and the use (as well as mastery) of technical materials such as ceramics, but also now a central stakeholder in this extraordinary adventure that has given rise to a new movement which looks destined for a fabulous future!

A closer look at Chanel Calibre 12.1

Chanel Calibre 12.1 is a movement operating at a frequency of 4 Hertz (28,800 vibrations/hour), with a power reserve of 70 hours and COSC-certified precision (i.e. an average daily variation in rate of between -4 sec/+6 sec).

This movement currently equips the new J12 in 38mm. Recently, a smaller version has been added to the new J12 33mm models under the name of Calibre 12.2. Chanel is thus expanding its offer of automatic watches equipped with its in-house calibre.

Chanel and the G&F Châtelain Manufacture: watchmaking at the cutting edge

The origin of this column was a visit to the heart of the G&F Châtelain Manufacture. This type of visit is quite rare, and it is with a feeling of being greatly privileged that I drank in all I was able to see – notably in terms of the whole design process and all the way through to the various tests that the watches undergo once their design is approved.

R&D Department: Technical bureau and prototyping

The Watchmaking design studios are located in Paris and overseen by Arnaud Chastaing. When a new watch is created, a file including marketing and design specifications is compiled in Paris and then sent to the technical bureau in La Chaux-de-Fonds.

A first aesthetic prototype is created by 3D printing, in order to have the design department approve the first renderings. At the end of this stage, a full-fledged technical file is created, comprising all the necessary elements: exploded views, types of finishes, dimensions, materials, etc.

Each element is approved by each profession (watchmakers, gemsetters, etc.), because each aesthetic decision and every choice may have a technical impact (durablity, water-resistance, etc.). After-sales service is integrated into the development process, as G&F Châtelain has understood that experience and feedback from customer service and the market are very important!

A series 0 (zero) is born and undergoes the homologation tests that we discovered later.

Approval testing laboratory

This internal laboratory was developed by the Manufacture with the aim of testing, if not all, at least the maximum number of situations that a Chanel watch could encounter, naturally with the aim of being able to cope with such conditions.

Five test centres await the Chanel watches: one involving shocks, another climate factors, a third magnetism issues, a fourth wear & ageing and a fifth devoted to expertise.

During the time spent in each of these test centres, the watch will endure all manner of constraints. At the end of the testing process, it must demonstrate its ability to continue running smoothly after thus being subjected to simulations of repeated falls and shocks.

Whether simulating a critical environment (temperature, humidity, exposure to UV, saline environment, etc.); wear and tear caused by friction; or even more impressively reproducing human sweat with several types of synthetic perspiration whose composition varies according to the type of geographical context (Europe, Africa, Asia, etc.): nothing is left to chance when it comes to ensuring the durability of Chanel watches!

The many other test centres will put the watch, its bracelet and even its case under various stresses and strains. All the homologation tests conducted enable Chanel watches to meet watchmaking standards. The watches that enter this laboratory undergo more than 3,000 cycles (tests), a total of 24,000 hours of controls – which is honestly pretty impressive, isn’t it?

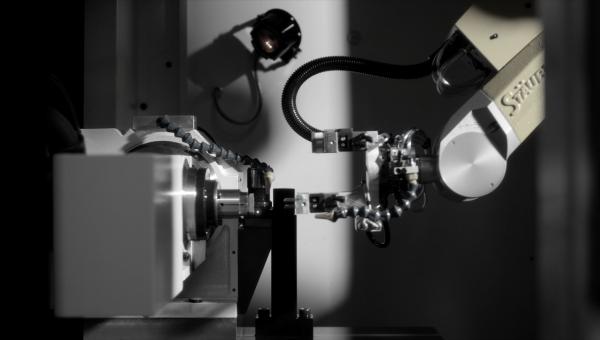

Metal component production

In the course of our tour, we entered corridors where the smell of grease gets stronger and stronger. This meant we were approaching the huge bar-turning machines and other CNC (numerically controlled) machines with which the factory is equipped.

Within the G&F Châtelain Manufacture, work on numerically controlled machines such as the magnificent Mazak bar-turning machine we were shown represents an element of fundamental importance. The technicians operating these machines must be regularly trained to master both the programming and maintenance of such equipment worth several hundred thousand francs (or even millions...).

Gemsetting workshop

Gemsetting is the art of setting a stone on a metal part. It is also a major field of competence that the G&F Châtelain Manufacture can claim to possess and in which it has achieved acknowledged mastery and expertise! Thanks to a team of in-house gemmologists, the gemsetting workshop also has the capacity to perform in-house alterations on stones.

The overriding aim of gemsetting workshops is to highlight a precious stone destined for a watch and/or a piece of jewellery.

No less than 95% of watchmaking gemsetting operations are carried out in-house at G&F Châtelain. None of it is done mechanically and everything is set by hand, whether setting with mechanical preparation (industrial machining to prepare the part to be set); traditional setting (preparation and setting are done by hand); or hammered setting, also called Haute Joaillerie along with the most prestigious gemsetting techniques.

Chanel ceramics

One of the strengths of the G&F Châtelain Manufacture lies in its expertise when it comes producing its own ceramics. Ceramic is a very hard and light material, which has many advantages for watchmaking. Other advantages such as its non-magnetic properties make it an ideal material when properly shaped.

There are several types of ceramics depending on the basic material used. These include tableware (porcelain), sanitary appliances and radars that involve ceramics with piezoelectric properties (ultrasound image applications). In watchmaking, ceramics based on zirconium oxide or aluminium oxide are used. G&F Châtelain chose zirconium oxide for its aesthetic properties after polishing, offering magnificent shimmering reflections.

The production of ceramics is based on four key stages: feedstock production, injection moulding, debinding and sintering. In a Watchmaker’s Chronicles article dedicated to Hublot ceramics, I describe in detail the complete manufacturing process and I strongly invite you to go and have a look at it if you have not already done so. HERE

What is important to remember about Chanel's particular approach to ceramics is that, in addition to controlling the manufacturing process from A to Z, the entire production is carried out in-house, including the preparation of the powder upstream of feedstock production so as to ensure the purity of this key component!

The final result is a ceramic case ready to accommodate the superb 12.1 movements we mentioned earlier!

Chanel, a complete watch Manufacture

This is where I end this column, having reported on my visit to the G&F Châtelain Manufacture and given you a different vision of the House of Chanel. From its importance in the watch industry to its central role as well as the magnificent products offered by the brand, it seems to me that Chanel is a complete watch Manufacture (and probably more so than many of its competitors).

Chanel is an admirable brand and, in my view, demonstrates vividly proven watchmaking expertise, mastering absolutely all aspects in the production of a watch – from its aesthetic development to the production of the movement and the case housing it. As far as the joint adventure with the Kenissi Manufacture is concerned, it seems to me that the future is pretty bright!

Thank you for reading!